Choosing the Right Plastic: HDPE or PET for Packaging Needs

When it comes to packaging products, selecting the appropriate plastic material is crucial. Two commonly used plastics in the industry are High-Density Polyethylene (HDPE) and Polyethylene Terephthalate (PET). Understanding their unique properties and characteristics can help you make an informed decision about which plastic is best suited for your packaging needs. In this blog post, we'll delve into the key factors to consider when choosing between HDPE and PET plastics.

HDPE and PET: A Closer Look

- HDPE (High-Density Polyethylene)

HDPE is a versatile thermoplastic polymer made from petroleum. It boasts a high strength-to-density ratio, excellent chemical resistance, and durability. Commonly used in packaging, such as bottles, containers, and bags, HDPE finds applications in various industries, including pipes, geomembranes, and toys. It is a cost-effective material that is widely recycled.

- PET (Polyethylene Terephthalate)

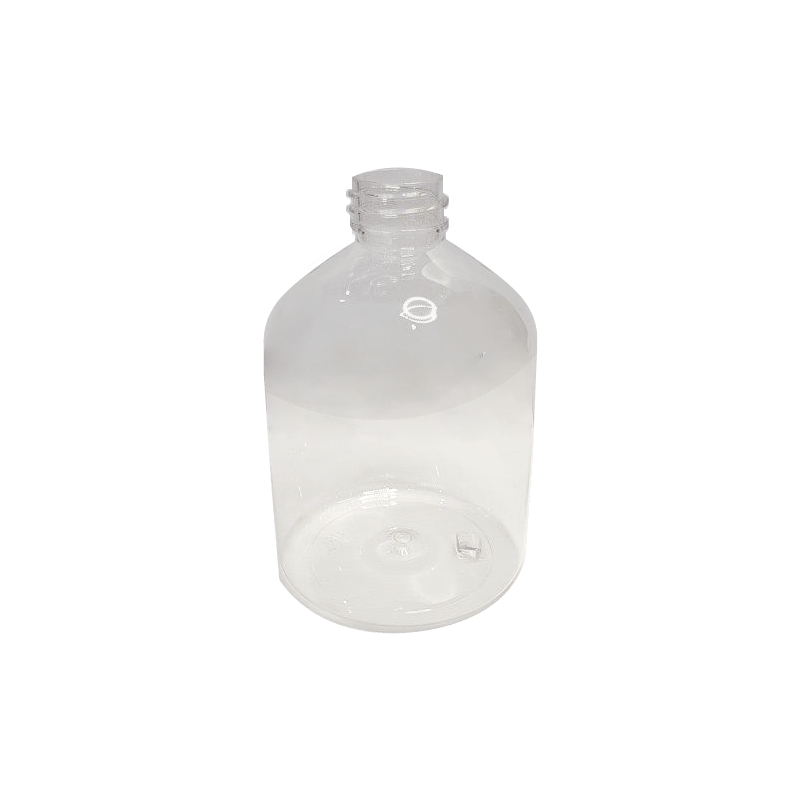

PET is a type of polyester widely employed in the production of plastic bottles for beverages and food items. Known for its strength, transparency, and lightweight nature, PET is suitable for packaging applications. It is commonly used for carbonated drinks, water, juices, and other liquid products. PET is also utilized in fibers for textiles and carpets. PET plastics are recyclable and commonly collected for recycling purposes.

Properties and Strengths

HDPE:

- High chemical resistance makes it suitable for packaging cleaning solutions, chemicals, and pharmaceuticals.

- Offers excellent moisture barrier properties and impact resistance, ideal for durable containers.

PET:

- Transparent, lightweight, and excellent clarity, making it a preferred choice for beverages and cosmetic items.

- Provides good gas barrier properties, preserving the freshness and aroma of the contents.

Application Considerations

Consider the specific requirements of your product:

- HDPE is well-suited for products that require chemical resistance, durability, and impact resistance.

- PET is often preferred for products that benefit from transparency, such as beverages and cosmetic items.

Recycling and Sustainability

Both HDPE and PET plastics are recyclable, making them environmentally friendly choices. PET is highly recyclable and can be transformed into various products, including new packaging containers. Consider the recycling infrastructure and availability in your region to make an informed sustainability decision.

Regulatory Compliance

Ensure that your chosen plastic meets regulatory requirements for your specific industry. HDPE and PET plastics have approvals for food contact applications, but it's essential to verify compliance with local regulations and safety standards.

Cost Considerations

Evaluate the cost implications of HDPE and PET plastics based on factors such as raw material prices, manufacturing processes, and supply chain considerations. The cost of each plastic can vary, so assess your budget and long-term packaging requirements.

Choosing the right plastic, whether HDPE or PET, is essential to ensure product integrity, safety, and sustainability. Consider the properties, strengths, application requirements, recycling capabilities, regulatory compliance, and cost factors when making your decision.

Primo Plastics offers a wide range of packaging solutions in both HDPE and PET plastics, tailored to meet your specific needs. Consult with our experts to determine the most suitable plastic for your packaging requirements and optimise the success of your products.